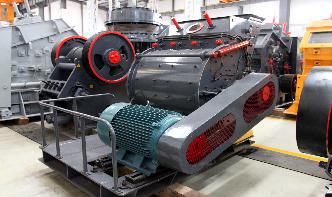

This machine is widely used in mine ore crushing, recycling of construction waste, construction aggregate, highway, railway, bridge and the production of construction industry. It is widely used in all kinds of hardness of rock materials and ore crushing, such as granite, diabase, basalt, shale, sandstone, quartz stone, gravel, limestone, iron ore, copper ore, manganese ore, coal, nonferrous .

Mining Processing Machinery Used In Copper Mining