AUC is the region's premier Englishlanguage University — an essential contributor to the social, political and cultural life of the Arab world. It also serves as a crossroads for the world's cultures: a vital, vibrant forum for reasoned argument, spirited debate and understanding across cultures.

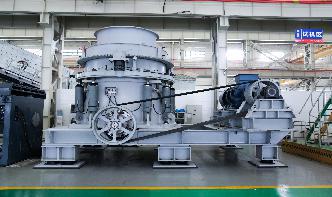

Ball Mill