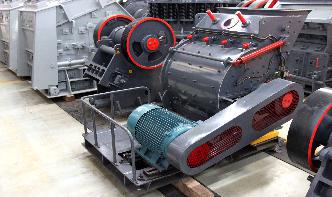

gold copper iron peru; magnetic separator for iron ore chips; reliable air flotation machine; need investor for copper and iron ore mine grinding ball mill; gold flotation cells vs iron ore magnetic separator; iron ore processing flotation machines; gravel iron ore gold inclined horizontal silica gold belt co; oem custom cast iron manhole cover ...

iron ore processing versus sulfur or processing