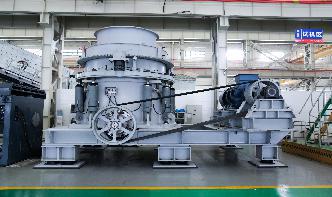

The smaller the particle size of steel slag powder, the . vertical mill and roller mill, while there are few researches on other measures, . X ray diffraction (XRD), using a D6000 diffractometer with nickel filtered Cu Kαl radiation. Slag Grinding Plant Chaeng. EPC turnkey services for slag / steel slag / nickel slag / manganese slag powder .

nickel slag powder grinding mill