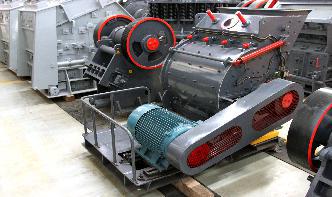

Introduction to rubber processing and safety issues ... raw rubber, process oils, carbon black, bulk fillers, and rubber . ... finished mixture is known as compound and is the material . that is processed into rubber articles by moulding, extrusion, calendering etc. Bale cutting . Before being added to the mixer the rubber may need to .

Introduction to rubber processing and safety issues