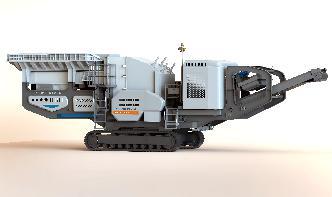

one SAG mill ( dia.(m)* length(m)) following two parallel ball mills (5dia.(m)*7lenght(m)). The aim of this research work was to investigate on the ball filling estimation of Miduk semiautogenous (SAG) Mill via an utilized method. Miduk SAG Mill circuit is shown in Figure 1. Figure 1: Diagram of Miduk Copper Complex SAG Mill Methods

A Method to Determine the Ball Filling, in Miduk Copper ...